uvex pheos E-S-WR

Helmets that are intended to be used in environments where employees are working with live or close to live parts need to be tested for electrical insulation using EN 50365.

The uvex pheos E-S-WR is ideally suited to electrical work with a fully enclosed helmet shell and certification in accordance with EN 50365 (1,000 Volt AC). The sturdy, rigid helmet shell also easily withstands pressure from the side, and fulfills all safety-related requirements for construction or industrial work.

✔ Suitable for use by electricians as helmet shell is fully enclosed

✔ Meets standard EN 397 and additional requirements for very low temperatures (-30 °C) and molten metal (MM) splash and is approved in accordance with EN 50365 (1000 V AC)

✔ Suspension harness with wheel ratchet for variable width adjustment

✔ Side Euroslot adapters (30 mm) for attaching earmuffs

✔ Shorter brim for a wider field of upward vision

uvex pheos K2P dielectric mounted earmuffs

uvex pheos K2P (mechanical connection)

- Dielectric muffs for uvex pheos visor system

- Mechanical connection

- Extra-soft memory foam ear cushions

- 360° rotation for standby and resting positions

- 30 decibels insulation

- Compatible only with uvex pheos visor 9906002, 9906005, 9906007

uvex pheos K2P (magnetic connection)

- Dielectric muffs for uvex pheos visor system

- Magnetic connection

- Extra-soft memory foam ear cushions

- 360° rotation for standby and resting positions

- 30 decibels insulation

- Compatible only with uvex pheos visor 9906003, 9906006, 9906008

uvex pheos visor

The uvex pheos visor can be locked above the helmet shell when not required, while the hearing protection can be folded back. Everything fits closely to the helmet and is perfectly balanced - ensuring maximum comfort and freedom of movement. There is no unnecessary weight to strain the muscles on the neck.

Visors coated with uvex supravision excellence are anti-fog (at least 16 seconds, norm requires 8 seconds) on the inside, while the outside offers extreme scratch and chemical resistance. The anti-fog coating is permanent and won’t wash off, even after repeated cleaning. The visors are also easy to clean and less susceptible to dirt due to the non-stick nanotechnology.

✔ Polycarbonate visors with uvex supravision excellence coating technology

✔ Available with two alternative mountings: mechanical levers or automatic magnetic locks

✔ Visors uvex pheos SLB 1 and uvex pheos SLB 2 can be combined with the uvex pheos E-S-WR safety helmet

✔ Meets standards EN 166 and EN 170, and also certified for areas of application 3 (liquids) and 9 (molten metal and hot solids)

uvex pheos SLB 1 (article number 9906005 and article number 9906006) visors are certified in accordance with GS-ET 29 as Class 1 visors for protection from electrical arcs (4 kA)

HexArmor safety gloves

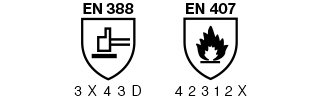

Gloves are a crucial piece of PPE for electrical workers and need to consist of high dielectric and physical strength, with flexibility and durability to mitigate the impact of an arc flash. The below gloves have been certified using the ANSI arcman test in accordance with ASTM F2675 and PPE selection standard NFPA 70E. The gloves are Categorised as Cat II Intermediate PPE under EU regulation 2016/245. These ratings are based on Hazard Risk Category (HRC) standards and the Arc Thermal Protective Value (ATPV). HRC is the safety standard that shows the minimum amount of PPE protection a worker needs based upon the potential exposure to a hazard, ranging from 0 to 4, with 4 being the highest risk. ATPV is the incident energy needed to cause a second-degree burn; this value is provided in calories per centimetre squared (cal/cm²).

| Hazard risk category | Required minimum arc rating of PPE cal/cm2 |

| HRC 1 | 4 |

| HRC 2 | 8 |

| HRC 3 | 25 |

| HRC 4 | 40 |

HexArmor Chrome SLT® 4061

- Arc Flash level 4 rating: lab tested in accordance with HRC ATPV at 46 cal/cm2

- Goatskin leather palm provides a traditional style of comfort and grip

- Full aramid liner for 360° cut protection

- Slip fit cuff assist a quick on and off between tasks

- Grip in dry or light oil situations

- Available sizes: 6/XS to 13/4XL

HexArmor Chrome SLT® 4062

- Arc Flash level 4 rating: lab tested in accordance with HRC ATPV at 46 cal/cm2

- Goatskin leather palm provides a traditional style of comfort and grip

- Stitched with Aramid thread

- Full aramid liner for 360° cut protection

- Extended safety cuff for easy on and off

- Grip in dry or light oil situations

- Available sizes: 6/XS to 12/3XL

HexArmor Helix® 2082

- Arc Flash level 1 rating: lab tested in accordance with HRC ATPV at 8.6 cal/cm2

- 13-gauge, flame-resistant aramid and wool blend shell

- Flexible neoprene/nitrile blend palm coating for superior grip and abrasion resistance

- Launderable for extended life

- Grip in dry, oil, or wet situations

- Available sizes: 7/S through 11/XXL