How to clean and store your uvex head protection

Ensuring your head protection is worn and cared for correctly is key to remaining safe. Industrial helmets are intended primarily to provide protection to the wearer against falling objects and consequential brain injury and skull fracture. It's therefore essential to look after your protective equipment and check your head protection is still suitable to perform, should the worst happen.

Cleaning industrial safety helmets

Any plastic parts of the helmet can be cleaned with water and commercially available cleaning agents and disinfected using commercially available disinfectants. Do not clean helmets with nonapproved solvents. Please check with your uvex representative if in doubt.

Cleaning industrial bump caps

Remove light soiling with a soft brush/damp cloth. The textile component can be washed by hand with a mild cleaning agent. Complete industrial bump caps can be disinfected using a mild, commercially available disinfectant.

Maintaining industrial safety helmets

Regularly check your helmet for damage and make sure that the interior of the helmet is connected to the helmet shell. Replace your helmet if it has taken a hit or undergone any impact or is in any way damaged. The helmet may only be modified or altered using tools approved by the manufacturer.

Maintaining industrial bump caps

Regularly check your cap for damage, cracks and distortion and replace your cap if necessary. Replace your industrial bump cap if it has undergone any impact – even if there is no visible damage.

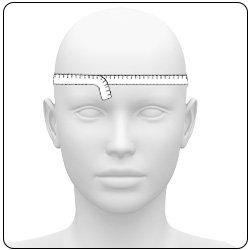

Find the right safety helmet size

A safety helmet should be neither too tight nor too loose on your head so it's important to find the right safety helmet size by measuring your head circumference.

Storage

Store safety helmets/industrial bump caps at room temperature in a dry room; avoid strong sunlight (e.g. do not store the safety helmet/industrial bump cap on the rear window shelf of a car or the front seat of a van). Helmets and caps can be stored for up to four years before being used for the first time. Remember to check the helmet for damage each time it is worn and always replace it after it has taken an impact or seen any other form of damage.

Checking expiry dates

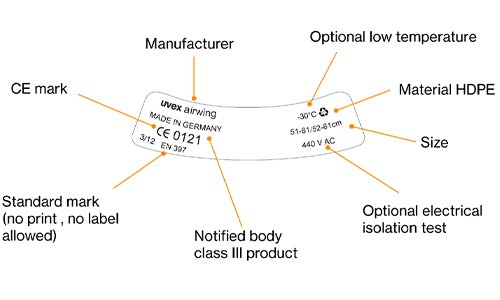

Helmets made of thermoplastic material must be replaced after 4 years. Helmets made of duroplastic materials (laminated helmets) may be kept for 8 years. Each helmet must be marked with its production date. Once the head protection has been used for the first time, we recommend using it for a period of four years. It is therefore important to note the date on which the item of headgear was first worn.

uvex head protection

Your uvex industrial helmet has been designed to protect against falling objects, swinging goods or contact with fixed but hazardous elements and conforms to EN 397 (industrial safety), or EN 12492 (mountaineering/climbing). A bump cap is ideal to protect against minor bumps and scrapes and conforms to EN 812.