How uvex solved a £1M footwear problem for a leading car manufacturer

By replacing ineffective safety footwear with a more durable, high-performing alternative, uvex helped a major automotive plant improve worker safety, cut waste, and save over £1 million annually.

Background

A leading car manufacturer faced an ongoing issue at one of its primary production facilities. Employees were regularly reporting discomfort and a high turnover rates in their safety footwear. The plant operated in a demanding environment, especially in high-risk areas like the Body Shop, which made the problem increasingly difficult to ignore. The existing safety footwear, provided by a previous supplier, showed rapid deterioration and failed to offer adequate protection, raising concerns among both workers and the health and safety team.

Identifying the problem

A uvex expert was brought in to assess the situation and conducted an in-depth on-site survey. The focus was the Body Shop, which housed the highest concentration of workers and the most rigorous physical conditions. The findings clearly showed:

- Comfort decline: Workers reported their boots became uncomfortable within a few months, leading to sore and aching feet.

- Slip hazards: The soles lost grip quickly due to continuous exposure to hydraulic fluids and hard concrete flooring.

- Material breakdown: The leather was soft and degraded rapidly, especially when exposed to chemicals. Even laces snapped frequently under normal wear.

- Insufficient protection: The previous boots held only an S1P safety rating, whereas the conditions demanded S3-rated protection.

Trial and introduction of new footwear

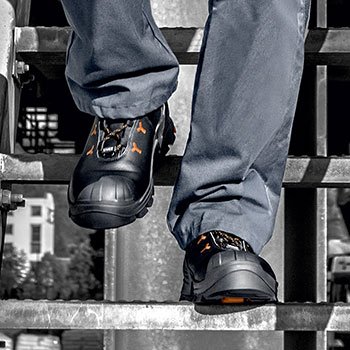

In response, uvex introduced a trial of its uvex 2 safety boots and shoes, selected for their higher durability and full S3 safety rating.

uvex understands that the best PPE is the PPE that’s worn consistently. That’s why the uvex 2 safety footwear has been designed with WEARABILITY in mind. At uvex, WEARABILITY goes beyond comfort; it’s about designing PPE that actively supports the wearer without hindering their work. It must achieve the right balance of fit, comfort, performance, and style, which, based on our experience, are key to driving both compliance and protection.

It’s also of note that all uvex footwear is manufactured under rigorous, internationally recognised standards, including ISO 9001 for quality management, ISO 14001 for environmental responsibility, and ISO 45001 for occupational safety.

Over a six-month period, the trial yielded overwhelmingly positive results:

- Worker endorsement: Employees consistently reported improved comfort and durability. The footwear held up well in the plant’s demanding environment.

- Safety compliance: The upgrade to S3-rated boots met all necessary safety criteria, earning approval from the health and safety team.

- Positive engagement: During the company's welfare day, employees shared unsolicited praise for the new boots, stating a clear preference over the previous supplier's product.

Financial and operational impact

Working with a company representative, the uvex expert calculated the broader financial impact of the footwear change. The findings were significant:

- Annual savings: The longer lifespan of the uvex boots (18 to 24 months compared to just six) translated into a savings of approximately £1,000,000 per year.

- Reduced waste: Fewer replacements meant less product heading to landfill, aligning with the company’s sustainability goals.

- Lower admin costs: With less frequent stock rotation and order management, internal administrative costs also dropped noticeably.

Health and well-being benefits

The occupational health team noticed tangible improvements among workers:

- Fewer complaints: There was a marked reduction in foot-related issues once the uvex footwear was implemented.

- Proactive health measures: Plans were put in place to further support workers with insoles and on-site fitting sessions, ensuring ongoing comfort and health.

Long-term success

Years after the switch, the footwear remains a consistent performer. No recurring issues have been reported, including common ones like lace degradation. The site has since become a benchmark for successful footwear integration within the company’s operations.

Conclusion

What began as a discomfort and durability issue turned into a wide-reaching transformation. By identifying the root cause, trialing a better solution, and backing it with data, the team not only improved worker satisfaction and safety but also delivered substantial financial and operational gains and all without compromising on compliance or comfort.