Lens technologies

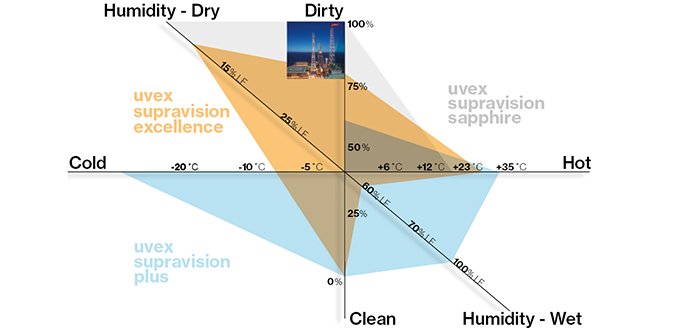

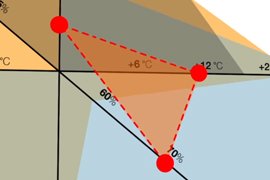

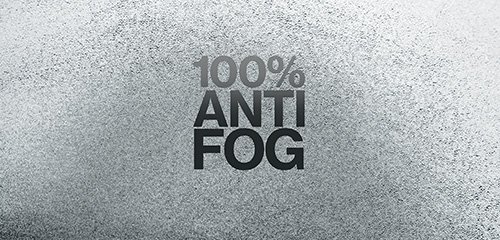

uvex’s pioneering lens coatings deliver the very best in German engineering. Developed in our own manufacturing facilities in Fürth, Germany, our lens coatings are permanent even after repeated cleaning. This offers great value for money and means you can get on with the job at hand without any distractions from your eyewear.